The right know-how for your

individual automation and test requirements

DESIGN

With many years of experience, we carry out designs on the basis of the Autodesk Inventor CAD system. Further tools such as the Vault data management software enable a reliable process when handling CAD data.

SOFTWARE DEVELOPMENT

Software development: Mastery of all programming languages that are relevant in our sector (C, C++, C#, LabVIEW, Step7, CAPL, etc.) enables us to fulfill virtually any customer requirement. Our software moves systems with maximum reliability, ease of operation, configurability, and expandability.

IMAGE PROCESSING (2D + 3D)

Image processing: With a wide range of industrial cameras and the HALCON proprietary program library with algorithms for image processing and machine vision, we can perform many tasks efficiently and cost-effectively. Image processing and image display are completely integrated into Drive.Studio.

ROBOTICS

Robotics: The use of robots in test systems enables significantly more efficient and universal test systems. Using robots from ABB, COMAU, FANUC, KUKA and STÄUBLI, we can offer test systems that respond flexibly to variant diversity and changing requirements.

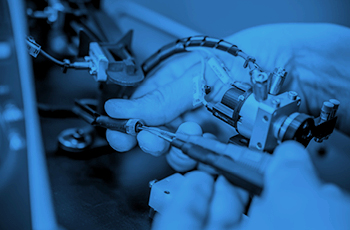

MEASUREMENT TECHNOLOGY

Measurement technology: A great deal of know‐how in the conception and implementation of measurement technology and close cooperation with component manufacturers ensures that measurement data is recorded precisely and suitably evaluated in our test systems.

LIGHT/LEDS

Through the development of LIN RGB modules, we have acquired a great deal of knowledge about light and LEDs. We use this knowledge for evaluation methods in order to test lighting components in test systems according to OEM requirements.

CONTROL TECHNOLOGY (REAL-TIME)

By using special Bosch and NI components, we offer programmable and dynamic real-time controls at runtime in our test systems. This results in a wide variety of new possibilities to simulate loads (e.g. position-dependent control parameters, etc.).

BUS SYSTEMS

We have had a command of communication standards such as LIN, CAN, FlexRay, Most, etc., and used them in software and test systems for many years. Tools such as CANoe are integrated into our software and enable our customers’ standards to be used.